Sourcing Company in Vietnam

Hello there! My name is Chris. I feel fortunate to have the opportunity to introduce myself to you. I am an American residing in the vibrant city of Ho Chi Minh, Vietnam, where I have been running a sourcing company since 2008. It's been an amazing journey so far. I'd like to know about you and your journey.🇻🇳

Thanks for considering my sourcing in Vietnam services. With a specialization in garment manufacturing and a broad range of experience encompassing hats, bags, shoes, wallets, plastic injection molding, metal parts, furniture, and ceramics, I am confident in my ability to cater to the needs of both creative start-ups and seasoned professionals. What is your area of expertise? How can I help you?

Thanks for considering my sourcing in Vietnam services. With a specialization in garment manufacturing and a broad range of experience encompassing hats, bags, shoes, wallets, plastic injection molding, metal parts, furniture, and ceramics, I am confident in my ability to cater to the needs of both creative start-ups and seasoned professionals. What is your area of expertise? How can I help you?

One of the aspects I genuinely enjoy about sourcing in Vietnam is the opportunity to bridge cultures and overcome language barriers. It brings me immense joy to help clients navigate the intricacies of Vietnamese manufacturing and gain a deeper understanding of the local culture. I am dedicated to ensuring a smooth manufacturing process, and I take pride in being your go-to person for all your product manufacturing needs in Vietnam.

When it comes to working with factories, I understand that every client has their own preferences. Many of my valued clients prefer to work directly with factories, which is precisely why I offer services like factory introductions and tours. By connecting you directly with reliable manufacturing facilities, I aim to facilitate transparent and productive collaborations. That is my sourcing in Vietnam style.

I would be delighted to schedule an introductory call at your convenience. This will give us the opportunity to discuss your specific requirements, explore the available options, and lay the foundation for a successful partnership. Please let me know when it would be a suitable time for us to connect.

Once again, I extend my sincere appreciation for considering my services. I look forward to the prospect of sourcing in Vietnam for you and assisting you in achieving your manufacturing goals. Feel free to reach out with any questions or to initiate our introductory call. Thank you! 🍀

When it comes to working with factories, I understand that every client has their own preferences. Many of my valued clients prefer to work directly with factories, which is precisely why I offer services like factory introductions and tours. By connecting you directly with reliable manufacturing facilities, I aim to facilitate transparent and productive collaborations. That is my sourcing in Vietnam style.

I would be delighted to schedule an introductory call at your convenience. This will give us the opportunity to discuss your specific requirements, explore the available options, and lay the foundation for a successful partnership. Please let me know when it would be a suitable time for us to connect.

Once again, I extend my sincere appreciation for considering my services. I look forward to the prospect of sourcing in Vietnam for you and assisting you in achieving your manufacturing goals. Feel free to reach out with any questions or to initiate our introductory call. Thank you! 🍀

6 Steps to Getting Factory Introductions

1. You fill in my contact form with your product details and factory requirements

2. My team checks our database or we ask around our network to identify the right factories for you

3. You pay our service fee

4. We have a Skype or WhatsApp chat to answer your questions and tell you what we know about the factories

5. We give you the factory contact details and you contact them directly

6. We standby to assist you in the future if you need other services like legal advice, set up offices, or quality control

2. My team checks our database or we ask around our network to identify the right factories for you

3. You pay our service fee

4. We have a Skype or WhatsApp chat to answer your questions and tell you what we know about the factories

5. We give you the factory contact details and you contact them directly

6. We standby to assist you in the future if you need other services like legal advice, set up offices, or quality control

Schedule a Factory Tour Today!

Here are questions that factories will ask:

1) What product do you want to produce in Vietnam?

2) Do you have any specific factory requirements?

3) Why are you looking for manufacturing in Vietnam as opposed to China or India?

4) What is your order quantity per design?

5) Do you have tech packs or technical specifications?

6) Do you have a website or online shop I can visit to learn more about you?

7) Which service are you interested in to start: factory introductions, factory visits, design, development or production?

2) Do you have any specific factory requirements?

3) Why are you looking for manufacturing in Vietnam as opposed to China or India?

4) What is your order quantity per design?

5) Do you have tech packs or technical specifications?

6) Do you have a website or online shop I can visit to learn more about you?

7) Which service are you interested in to start: factory introductions, factory visits, design, development or production?

Background About Me

I have been living here for 10 years and know many factories. I am not a sourcing company in Vietnam that works on commission basis. My clients pay me up front. I am a scout. I help you find the right factories fast and put you in direct contact with them.

The first step is for me to know clearly what your product is. The more details you share with me about your product the easier it is for me to identify a factory that can make it. The second step is to know any special requirements the factory must have like certification and size. I have created a contact form to make it easy for you to answer the questions I need to help you. If you have your product specs and are ready to meet factories then please fill out my contact form.

If you are new to manufacturing and just have questions then I'd be happy to answer your questions and give you my advice. I offer consulting which you can book online and chat with me on Skype. Or you can read my books which systematically cover all the topics you should be familiar with before contacting overseas manufacturers. My specialty is apparel and I can help you with non-apparel.

The team I work with offers services like factory introductions, factory visits, audits, quality control and more. We do not work exclusively for any factory. We charge one service at a time and our rates are competitive. We aim to help you source quickly and become your long term sourcing support service in Vietnam. We can help you set up offices, register your business, hire staff and find places to live. If you pay us, you become part of our family.

First we need to know basic information. Are you a start up or are you an established business? Are you sourcing apparel or non-apparel? Do you want to work directly with the factory? Which sourcing service interests you the most? What is the problem you are facing? What are your business goals in Vietnam? Contact me, share your story, and let's see if we can get you up and running in Vietnam quickly.

I built this website many years ago knowing that Vietnam would grow to be a powerful manufacturing country. Instead of building my own sourcing company in Vietnam I teamed up with a veteran sourcing expert who already had a team of people who can execute the work you need. My role is marketing and pre-sales. I listen to what you need and offer you options. Professionals who have been sourcing in China for many years need different services compared to start ups who have never sourced manufacturing overseas. My job is to hear your story and then quickly point you in the right direction. I am very good as working with both professionals and start ups.

Do you want to work directly with the factory? Nowadays most people want to work directly with factories and don't really need a sourcing company in Vietnam. Myself and the team I work with are not trying to be your agent. We will not put ourselves between you and the factory. On the contrary. We introduce you directly first, if you need additional services, we will be there for you.

The first step is for me to know clearly what your product is. The more details you share with me about your product the easier it is for me to identify a factory that can make it. The second step is to know any special requirements the factory must have like certification and size. I have created a contact form to make it easy for you to answer the questions I need to help you. If you have your product specs and are ready to meet factories then please fill out my contact form.

If you are new to manufacturing and just have questions then I'd be happy to answer your questions and give you my advice. I offer consulting which you can book online and chat with me on Skype. Or you can read my books which systematically cover all the topics you should be familiar with before contacting overseas manufacturers. My specialty is apparel and I can help you with non-apparel.

The team I work with offers services like factory introductions, factory visits, audits, quality control and more. We do not work exclusively for any factory. We charge one service at a time and our rates are competitive. We aim to help you source quickly and become your long term sourcing support service in Vietnam. We can help you set up offices, register your business, hire staff and find places to live. If you pay us, you become part of our family.

First we need to know basic information. Are you a start up or are you an established business? Are you sourcing apparel or non-apparel? Do you want to work directly with the factory? Which sourcing service interests you the most? What is the problem you are facing? What are your business goals in Vietnam? Contact me, share your story, and let's see if we can get you up and running in Vietnam quickly.

I built this website many years ago knowing that Vietnam would grow to be a powerful manufacturing country. Instead of building my own sourcing company in Vietnam I teamed up with a veteran sourcing expert who already had a team of people who can execute the work you need. My role is marketing and pre-sales. I listen to what you need and offer you options. Professionals who have been sourcing in China for many years need different services compared to start ups who have never sourced manufacturing overseas. My job is to hear your story and then quickly point you in the right direction. I am very good as working with both professionals and start ups.

Do you want to work directly with the factory? Nowadays most people want to work directly with factories and don't really need a sourcing company in Vietnam. Myself and the team I work with are not trying to be your agent. We will not put ourselves between you and the factory. On the contrary. We introduce you directly first, if you need additional services, we will be there for you.

Example of a Factory in My Network

SCAVI is the best lingerie garment company in Vietnam. SCAVI is a French garment manufacturer with five factories in Dong Nai, Danang, Hue, Lam Dong and Laos. It was established in 1988. They specialize in luxury intimates, core intimates, underwear, night wear, swimwear and sportswear. They offer the following services:

Design

Material Development

Material Sourcing

Pattern Development - Modelism - Technical Fitting

Sample Making

Planning

Purchasing

Manufacturing

Logistics

From its establishment, the company has been led by Tran Van Phu, chairman-founder-CEO, who had held many key positions at French companies before founding the company. In 2011 he wrote a book: "Faire Repartir la France et l’Europe – la démocratie volontaire" ("Relaunch France and Europe - The Voluntary Democracy") - Le Cherche Midi Edition-2011. The book won the reputable Cresus Prize - French National Assembly in Paris in July 2011.

SCAVI is a pioneer in social responsibility. They founded the International Hub Club. They support education by funding kindergartens for children of the Group’s members. The schools use the Montessori Method.

If you need help connecting with SCAVI, I can help you. Contact me for help.

Design

Material Development

Material Sourcing

Pattern Development - Modelism - Technical Fitting

Sample Making

Planning

Purchasing

Manufacturing

Logistics

From its establishment, the company has been led by Tran Van Phu, chairman-founder-CEO, who had held many key positions at French companies before founding the company. In 2011 he wrote a book: "Faire Repartir la France et l’Europe – la démocratie volontaire" ("Relaunch France and Europe - The Voluntary Democracy") - Le Cherche Midi Edition-2011. The book won the reputable Cresus Prize - French National Assembly in Paris in July 2011.

SCAVI is a pioneer in social responsibility. They founded the International Hub Club. They support education by funding kindergartens for children of the Group’s members. The schools use the Montessori Method.

If you need help connecting with SCAVI, I can help you. Contact me for help.

How to calculate import duties from Vietnam to USA

Step 1 is to figure out what is the HS Code of your product. Step 2 is to look up your HS Code in the Harmonized tariff schedule. You will see the duty rate listed next to your HS Code. Done. Sounds easy right? Like putting socks on a rooster. The safest thing to do is hire a certified customs broker who classifies many products every day. The problem is, customs brokers will only do a classification for you if you are a lucrative client shipping containers on a regular basis. That's how they make their living. So what can you do? Sail out into the open ocean yourself, do your own classification, let me chart the way for you.

First thing you need to keep in mind is that when your goods get to the USA port, it's the US Customs and Border Protection (CBP) officer that will either approve or disapprove the HS Code classification declared on the shipping documents. Their job is to make sure you pay the right import duty. If the CBP decides your classification is wrong then you risk delaying the delivery of your goods and being labeled as an offender which could delay future shipments. You will have to pay the remaining tax to get your goods released. If you are caught incorrectly classifying your product, your certified customs broker who made the classification for you, has their neck in the guillotine too. They can have their license revoked and be out of work if they are caught multiple times classifying products with low taxes. The broker can petition the decision to save their neck but they waste time petitioning and time is money - lost.

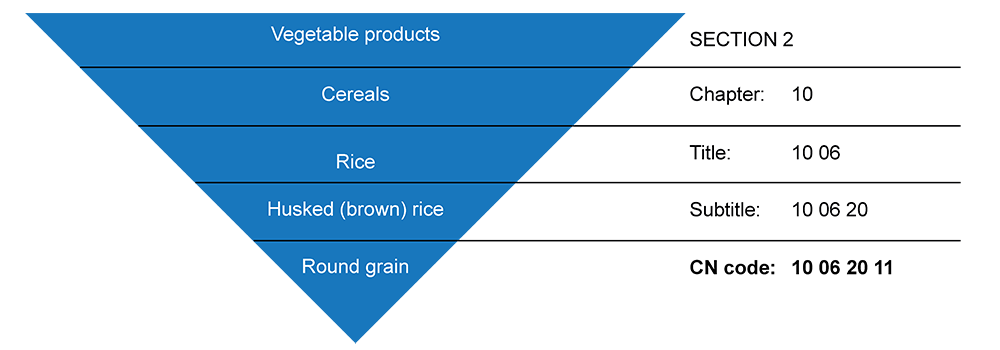

Here is what the classification hierarchy of round grain husked rice looks like.

First thing you need to keep in mind is that when your goods get to the USA port, it's the US Customs and Border Protection (CBP) officer that will either approve or disapprove the HS Code classification declared on the shipping documents. Their job is to make sure you pay the right import duty. If the CBP decides your classification is wrong then you risk delaying the delivery of your goods and being labeled as an offender which could delay future shipments. You will have to pay the remaining tax to get your goods released. If you are caught incorrectly classifying your product, your certified customs broker who made the classification for you, has their neck in the guillotine too. They can have their license revoked and be out of work if they are caught multiple times classifying products with low taxes. The broker can petition the decision to save their neck but they waste time petitioning and time is money - lost.

Here is what the classification hierarchy of round grain husked rice looks like.

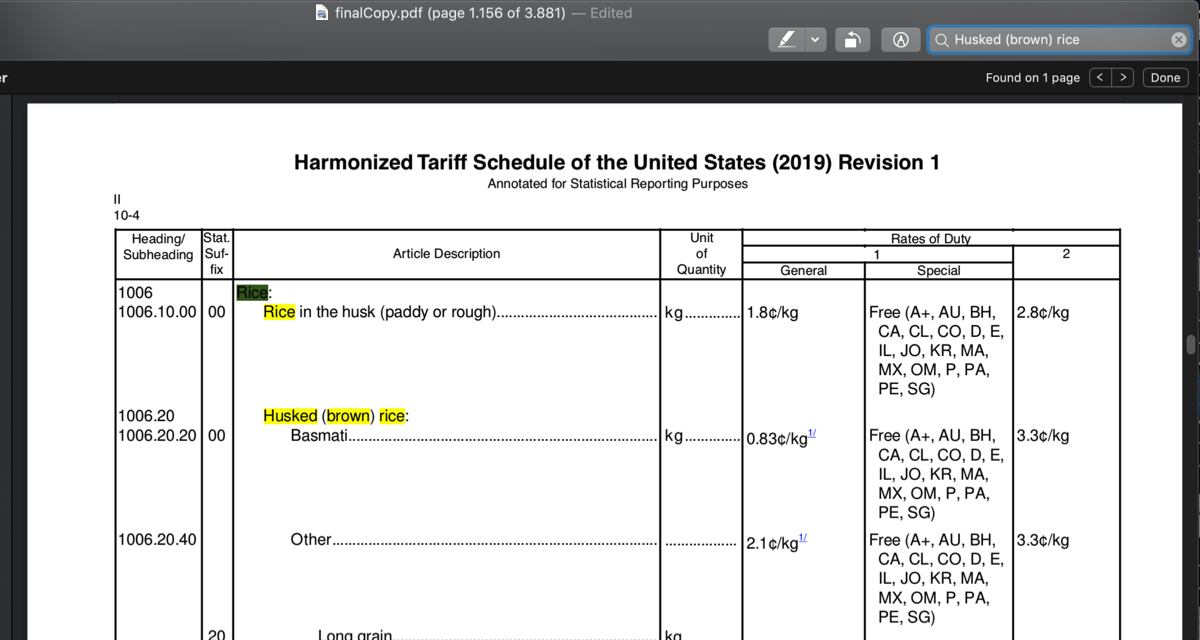

Try yourself. It will take you 10 minutes. I will show you exactly what to do. Some products are straight forward and easily classified.

1 Go to this CBP webpage and download the Full Document of the Harmonized Tariff Schedule. https://hts.usitc.gov/current

2 Search pdf document for Husked (brown) rice and you will see the duty rate.

1 Go to this CBP webpage and download the Full Document of the Harmonized Tariff Schedule. https://hts.usitc.gov/current

2 Search pdf document for Husked (brown) rice and you will see the duty rate.

In fact it is not that easy for most products because most products are composed of different materials. For example a t-shirt that made with cotton, viscose and spandex or a piece of furniture with metal, wood and plastic. It takes experience to know which classification yields the lowest duty rate and will be accepted by the CBP. Also, do you see the column labeled "special?" Figuring out how to benefit from he "special" takes time and know-how. This is the reason I recommend you hire a licensed customs broker to help you out.

There are 14,454 active licensed Customs brokers in the United States. They must pass an open book test with 80 multiple-choice questions testing their knowledge of The Harmonized Tariff Schedule of the United States (HTSUS), Title 19, Code of Federal Regulations, Specified Customs Directives and Customs and Trade Automated Interface Requirements document (CATAIR). If you can't find one to help you then you can also tap into the CBP resources.

This website provides U.S. merchandise trade and tariff data in a user friendly web interface. https://dataweb.usitc.gov

You can also request a ruling from the CBP via this webpage: https://erulings.cbp.gov/home

If you are willing to pay me then I can get the classification done for you. Please contact me for more information.

There are 14,454 active licensed Customs brokers in the United States. They must pass an open book test with 80 multiple-choice questions testing their knowledge of The Harmonized Tariff Schedule of the United States (HTSUS), Title 19, Code of Federal Regulations, Specified Customs Directives and Customs and Trade Automated Interface Requirements document (CATAIR). If you can't find one to help you then you can also tap into the CBP resources.

This website provides U.S. merchandise trade and tariff data in a user friendly web interface. https://dataweb.usitc.gov

You can also request a ruling from the CBP via this webpage: https://erulings.cbp.gov/home

If you are willing to pay me then I can get the classification done for you. Please contact me for more information.

Women's Apparel Manufacturing Agent

Do you need a women's apparel manufacturing agent in Vietnam? I can be your agent and produce women's apparel for you using both woven and knit fabric. I often introduce myself as a manufacturer because there is such a negative stigma about agents. The value I offer as a women’s apparel manufacturing agent in Vietnam is worth 100 good night sleeps. If you need an agent, then contact me. If you don’t need an agent then contact me anyway because I offer consulting that can save you time and money if you are new to women's apparel production in Vietnam.

My journey began in Vietnam 20+ years ago. I was hired as a country manager overseeing the production of 200,000 women’s woven fashion garments produced per month for shipment to Europe. With my finance background and understanding of the high street in the EU I mastered the art of working with Vietnamese suppliers, managing quality, developing samples with good designs using cutting edge fabrics and trims and managed to shipping on time 9/10 times.

Over the decades I have watched as buyers shifted from China, Hong Kong and Thailand to Vietnam to tap into the high quality, low cost Vietnam offered back then. I took my clients under my wings and navigated them through a war-torn country and shoId them how Vietnam was evolving into a modern society with the fastest rising middle class in Southeast Asia. I managed to get them capacity in my arsenal of reliable women’s woven fashion factories. Fast forward to 2019, getting capacity at low prices is as easy as winning the lottery. I win 9/10 times. Coats, blazers, trousers, blouses ,dresses, skirts and jump suits are what I know best. I know what can be made for the best price and quality in Vietnam. I have successfully shipped for many of the international labels like Escada, Jils Sanders and Max Studio. I develop 200 samples every month to offer my customers trending designs and showcase the latest fabrics my textile mills are offering me. I have a full technical design and QA team to ensure the manufacturing process runs smoothly and efficientlyI have built up a library of fabric suppliers over the year.

I source fabric out of China, Korea, Taiwan and Vietnam. The majority of the fabric we buy is ITY out of Korea. We have great sources for Georgette, Crepe, Chiffon, Cambric and Chintz. We get the fabric into Vietnam, to the factories and re-exported within 30 to 90 days.

The challenge we face today is that Chinese orders are flooding the Vietnamese market. On one hand it is good for Vietnam because factories are bursting at the seams but, on the other hand, it’s getting harder and harder to get capacity at cheap prices. If you are new to Vietnam then anticipate getting in line. Anticipate being offered high prices initially. Or, step in the front of the line with us and let us, get you, the right price quickly.

Customers want to deal directly with factories because they see it as a cheaper option. In reality it is not. While larger factories are easy to work with because they have merchandisers that speak English fluently, most of the larger factories have high MOQs and are fully booked with the Walmarts of the world. If you want to work with smaller MOQs and smaller factories like we do, then the language barriers become formidable and when problems happen, communication breaks down, delays happen. Our presence is required on site to solve the problems clearly and quickly. We add additional value on the client side as well. We have offices in the Europe and often visit clients to facilitate problem solving - clearly and quickly. Working without an agent can save money when everything goes well. Working with a women’s woven fashion agent in Vietnam like us, saves you money in the long run when you factor in unsellable goods, late shipment fees and last minute air shipment fees. Let us deal with sampling, production and shipment. Yes, we charge a commission but in the long run you will save money as well as get 100 good night sleeps seasons on end.

My journey began in Vietnam 20+ years ago. I was hired as a country manager overseeing the production of 200,000 women’s woven fashion garments produced per month for shipment to Europe. With my finance background and understanding of the high street in the EU I mastered the art of working with Vietnamese suppliers, managing quality, developing samples with good designs using cutting edge fabrics and trims and managed to shipping on time 9/10 times.

Over the decades I have watched as buyers shifted from China, Hong Kong and Thailand to Vietnam to tap into the high quality, low cost Vietnam offered back then. I took my clients under my wings and navigated them through a war-torn country and shoId them how Vietnam was evolving into a modern society with the fastest rising middle class in Southeast Asia. I managed to get them capacity in my arsenal of reliable women’s woven fashion factories. Fast forward to 2019, getting capacity at low prices is as easy as winning the lottery. I win 9/10 times. Coats, blazers, trousers, blouses ,dresses, skirts and jump suits are what I know best. I know what can be made for the best price and quality in Vietnam. I have successfully shipped for many of the international labels like Escada, Jils Sanders and Max Studio. I develop 200 samples every month to offer my customers trending designs and showcase the latest fabrics my textile mills are offering me. I have a full technical design and QA team to ensure the manufacturing process runs smoothly and efficientlyI have built up a library of fabric suppliers over the year.

I source fabric out of China, Korea, Taiwan and Vietnam. The majority of the fabric we buy is ITY out of Korea. We have great sources for Georgette, Crepe, Chiffon, Cambric and Chintz. We get the fabric into Vietnam, to the factories and re-exported within 30 to 90 days.

The challenge we face today is that Chinese orders are flooding the Vietnamese market. On one hand it is good for Vietnam because factories are bursting at the seams but, on the other hand, it’s getting harder and harder to get capacity at cheap prices. If you are new to Vietnam then anticipate getting in line. Anticipate being offered high prices initially. Or, step in the front of the line with us and let us, get you, the right price quickly.

Customers want to deal directly with factories because they see it as a cheaper option. In reality it is not. While larger factories are easy to work with because they have merchandisers that speak English fluently, most of the larger factories have high MOQs and are fully booked with the Walmarts of the world. If you want to work with smaller MOQs and smaller factories like we do, then the language barriers become formidable and when problems happen, communication breaks down, delays happen. Our presence is required on site to solve the problems clearly and quickly. We add additional value on the client side as well. We have offices in the Europe and often visit clients to facilitate problem solving - clearly and quickly. Working without an agent can save money when everything goes well. Working with a women’s woven fashion agent in Vietnam like us, saves you money in the long run when you factor in unsellable goods, late shipment fees and last minute air shipment fees. Let us deal with sampling, production and shipment. Yes, we charge a commission but in the long run you will save money as well as get 100 good night sleeps seasons on end.

Will the apparel trade in Vietnam be affected by Brexit?

Orders will shift from Vietnam to fast-fashion countries like Turkey, Italy, Portugal and Morocco if Brexit happens.

If Brexit happens then free trade agreements the UK has with countries like Cambodia will not be cancelled. This is a key point. The UK can’t and doesn’t want to cancel international free trade agreements that they signed with countries like Myanmar, Bangladesh and Cambodia while part of the EU. It will take years to cancel existing free trade agreements. In fact it will be the UK’s priority to preserve existing free trade agreements to promote trade. This means that apparel produced in Myanmar, Bangladesh and Cambodia will continue to get reduced tariffs even if UK exits the EU. There will not be a shift of orders from Myanmar, Cambodia or Bangladesh to Vietnam as we might think.

What will be an effect is changes in logistics. Frank Vossen, from Seditex Sourcing in Vietnam shared that Vietnamese factories serving European brands shipping into the EU will have to work with buyers to separate goods going to the UK vs goods going to other EU countries. The reason is that, if UK exits the EU then moving goods from EU to UK will incur costs and time delays due to new laws about importing and exporting goods across the UK/EU border. Before Brexit, a Vietnamese supplier would ship everything to Germany and then the goods would be distributed to UK via Germany easily. After Brexit, the shipments will have to be separated to avoid additional costs or delays. This translates to changes in logistics supply chains.

John Fraser, from HighFlyer Ltd., a manufacturer of women’s fashion made for the High Street of UK says, “our biggest concern is the UK consumer buying habits.” If the British people buy less due to difficult economic times, then the total number of orders will decrease.

Orders will shift from Myanmar, Bangladesh, Cambodia and Vietnam to fast-fashion countries like Turkey, Italy, Portugal and Morocco. Brands like Top Shop and Primark will choose the safer option to produce less with shorter lead times to minimize their inventory and sell through as much as they can before re-ordering. This means producing smaller order quantities closer to home with faster lead times: fast fashion. Vietnam is not close to UK compared to other EU manufacturing hubs so therefore Vietnam might see orders shift from Vietnam to fast-fashion countries.

Could China will be the winner of Brexit? China has what all other countries don’t have. China has quick and cheap access to classic and innovative fabrics. They still have competitively priced sewing services outside legacy industrial zones. China can source fabric from China, Taiwan or Korea better than any other apparel manufacturing country. The UK brands need classic fabrics for their season best sellers that repeat every year. They also need innovative fabrics to fashionable. There is limited capacity for fast fashion production in Turkey, Italy, Portugal and Morocco. There is limited supply of fabric in fast fashion countries. If China can offer fast fabric, fast sewing and fast shipping at the same price as Turkey, Italy, Portugal and Morocco then they have a chance to benefit from Brexit.

If Brexit happens then free trade agreements the UK has with countries like Cambodia will not be cancelled. This is a key point. The UK can’t and doesn’t want to cancel international free trade agreements that they signed with countries like Myanmar, Bangladesh and Cambodia while part of the EU. It will take years to cancel existing free trade agreements. In fact it will be the UK’s priority to preserve existing free trade agreements to promote trade. This means that apparel produced in Myanmar, Bangladesh and Cambodia will continue to get reduced tariffs even if UK exits the EU. There will not be a shift of orders from Myanmar, Cambodia or Bangladesh to Vietnam as we might think.

What will be an effect is changes in logistics. Frank Vossen, from Seditex Sourcing in Vietnam shared that Vietnamese factories serving European brands shipping into the EU will have to work with buyers to separate goods going to the UK vs goods going to other EU countries. The reason is that, if UK exits the EU then moving goods from EU to UK will incur costs and time delays due to new laws about importing and exporting goods across the UK/EU border. Before Brexit, a Vietnamese supplier would ship everything to Germany and then the goods would be distributed to UK via Germany easily. After Brexit, the shipments will have to be separated to avoid additional costs or delays. This translates to changes in logistics supply chains.

John Fraser, from HighFlyer Ltd., a manufacturer of women’s fashion made for the High Street of UK says, “our biggest concern is the UK consumer buying habits.” If the British people buy less due to difficult economic times, then the total number of orders will decrease.

Orders will shift from Myanmar, Bangladesh, Cambodia and Vietnam to fast-fashion countries like Turkey, Italy, Portugal and Morocco. Brands like Top Shop and Primark will choose the safer option to produce less with shorter lead times to minimize their inventory and sell through as much as they can before re-ordering. This means producing smaller order quantities closer to home with faster lead times: fast fashion. Vietnam is not close to UK compared to other EU manufacturing hubs so therefore Vietnam might see orders shift from Vietnam to fast-fashion countries.

Could China will be the winner of Brexit? China has what all other countries don’t have. China has quick and cheap access to classic and innovative fabrics. They still have competitively priced sewing services outside legacy industrial zones. China can source fabric from China, Taiwan or Korea better than any other apparel manufacturing country. The UK brands need classic fabrics for their season best sellers that repeat every year. They also need innovative fabrics to fashionable. There is limited capacity for fast fashion production in Turkey, Italy, Portugal and Morocco. There is limited supply of fabric in fast fashion countries. If China can offer fast fabric, fast sewing and fast shipping at the same price as Turkey, Italy, Portugal and Morocco then they have a chance to benefit from Brexit.

Please give me details about your background and manufacturing objectives.

1. Which styles do you want to manufacture first?

2. Do you have tech packs?

3. Do you have any special factory requirements?

4. Have you produced before? If yes, then in what country?

5. What quantity per style per color do you order?

6. Does your company have a website?

7. Do you want to work with an agent or directly with the factory?

8. Do you plan to visit Vietnam?

1. Which styles do you want to manufacture first?

2. Do you have tech packs?

3. Do you have any special factory requirements?

4. Have you produced before? If yes, then in what country?

5. What quantity per style per color do you order?

6. Does your company have a website?

7. Do you want to work with an agent or directly with the factory?

8. Do you plan to visit Vietnam?